- Home

- Products

- Vertical Machining Center

- Vertical 3 Axis Machining Center with Box Guideways

- ZF-1690B Vertical Machining Center

ZF-1690B Vertical Machining Center

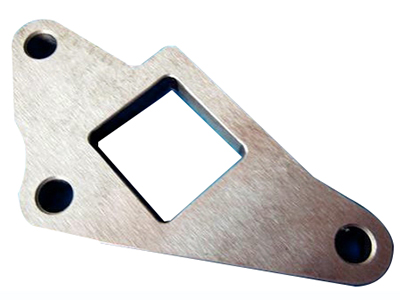

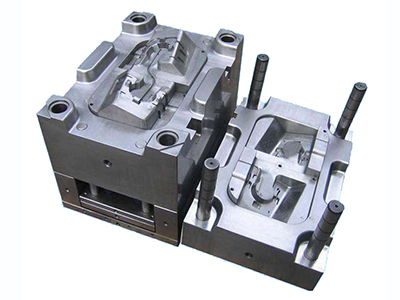

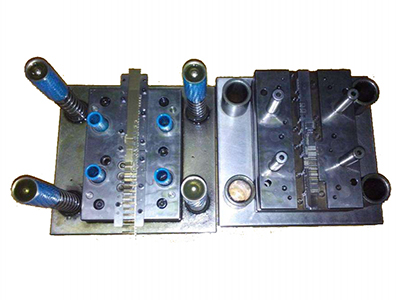

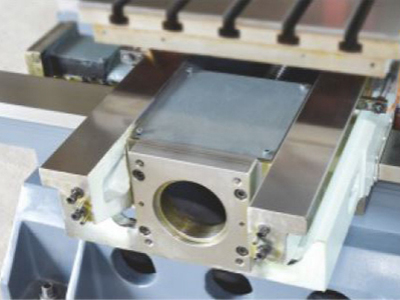

The ZF-1690B vertical machining center is specially engineered for the rough machining of different products like molds and dies. Milling is its primary processing method and it features a BT50 spindle with a speed up to 8000 rpm. Therefore, the equipment can meet the processing demands of most materials.

Parameters

| Mode | ZF-1690B |

| X/Y/Z axis travel (mm) | 1600×900×600 |

| Worktable area (mm) | 1800×900 |

| Maximum weight on table (kg) | 1600 |

| Distance between spindle center to column (mm) | 950 |

| Distance from spindle nose to table center (mm) | 160-840 |

| Three-axis motor power (kw) | 4.5/7/4.5 |

| X/Y/Z axis rapid feed (mm/min) | 15000/15000/12000 |

| Control system | MISUBISHI:M70A, FANUC:Oi-MD/Oi mate-MD, SIEMENS828D |

| Spindle taper | BT50 |

| Standard spindle speed (r.p.m) | 8000(6000) |

| Spindle horsepower (kw) | 22 |

| Air pressure (bar) | 6-7 |

| Machine dimension (mm) | 4510×3380×3500 |

| Machine weight (kg) | 15000 |

Features

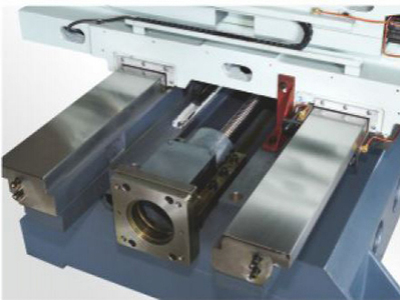

The three-axis slideway is plated with friction materials to make the guide rail smooth, thus improving its accuracy and efficiency.

Machining centers with box guideways feature high-speed ballscrews, reducing friction and increasing positional accuracy and efficiency.

Its wide front gate allows for easy loading and unloading of processed components and dies.

Machining center adopts Mitsubishi, FANUC, and Siemens components to ensure high security and performance.

Other Products

Contact Us

Dongguan Zefeng Intelligent Machinery Co., Ltd.

- Contact: Rui Xiao (Mr.))

- zefengznjc@sina.com

- +86-769-22992661

- +86-769-22111367