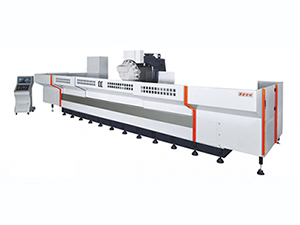

Vertical Machining Center

Vertical machining centers will be ideal equipment if you want to process parts using milling, tapping, and drilling processes. They are capable of working with a wide range of materials, such as metal, plastic, wood, and so forth. Our machines are also equipped with a tool magazine to ensure rapid automatic tool changeover and minimize downtime. There are three types of machining center available for selection according to different materials, precision and cutting forces.

-

- Vertical 3 Axis Machining Center with Box Guideways Our machining center with box guideways is ideal for the milling, drilling and tapping of high hardness metal materials or products large in size. This is largely due to the guideways and the machine tools are directly cast so that the spindle bearing is strong enough to handle tough jobs. The X/Y/Z axis travel of our machines is 800-1800mm, 500-900mm and 550mm-800mm respectively.

-

- Vertical 3 Axis Machining Center with Linear Guideways Are you looking for a machining center to carry out milling, drilling, and tapping processes with great precision? Here at Zefeng, we offer machining centers with linear guideways that are ideal for just those jobs. Their three-axis travel on the linear guideways minimize friction and maximizes the positioning precision. The machine is ideal for both mass production and small scale production. X/Y/Z axis travel is also available in ranges of 800-1300mm, 500-700mm and 550-700mm respectively.

-

- Vertical Machining Center, X/Y Axis Linear Guide Ways, Z Axis Box Guide Way This machining center is ideal for customers that need to carry out heavy machining processes, including milling, drilling, and tapping, with a high processing speed and accuracy. The X and Y axis are linear guideways, while the Z axis uses a box guideway to ensure the spindle can withstanding a strong force during processing, as well as ensure material moves quickly forward and backward. This guarantees both the machining accuracy and speed. The X/Y/Z maximum travel is up to 1800mm, 900mm, and 800mm respectively.

Other Products

Contact Us

Dongguan Zefeng Intelligent Machinery Co., Ltd.

- Contact: Rui Xiao (Mr.))

- zefengznjc@sina.com

- +86-769-22992661

- +86-769-22111367